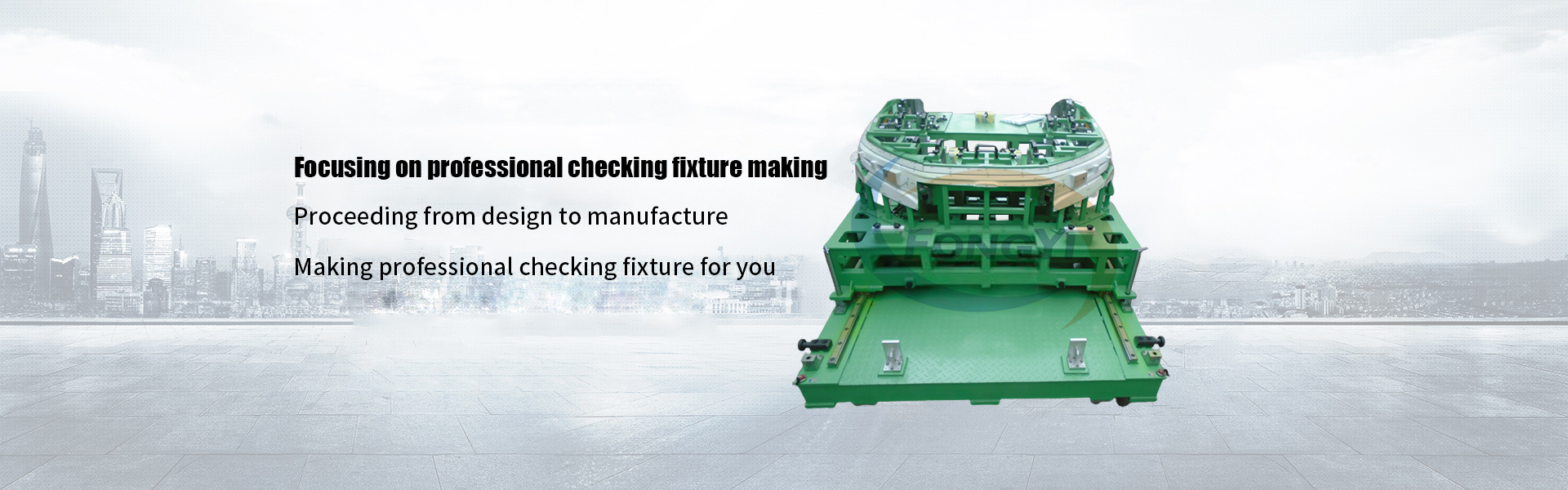

The skylight tester is used to simulate the skylight positioning and detect the parts around the installation of the skylight. Simulate the matching relation between the skylight and the surrounding surfaces, and simulate the matching relation between the standard skylight and the surrounding parts in the loading state. The weight is limited, so this tester is made of aluminum alloy hollow tube welding, heat treatment after welding, eliminate the internal stress, improve the strength of the tester.

Products

contact

DongGuan Fong Yi precision tooling Co.,Ltd.

Address : NO.2,Huamei Road,Xitailong Village Industrial Area, Shatian Town, Dongguan City,Guangdong Province.China

Tel: +86 769 88663970 -2

Fax: +86 769 88663975

E-mail: dgfongyi@vip.163.com;

FongYi Autoparts(WUHAN)CO.,Ltd.

Address : Crossroad between ChangXi and FuJi Road,Changfu Industrial park,Caidian District,WuhanCity,Hubei Province.China

Tel: +86 27 69575831/2/6

Fax: +86 27 69575837

E-mail: whfongyi@vip.163.com;

Industry dynamic

An introduction to the standard for measuring the quality of

Author:admin Addtion Date:2020-07-01 19:36:45 View:

The sunroof gage is a special measuring tool for automobile product inspection and provides relevant measuring data. With the change of production mode, the development of inspection tool is constantly updated and gradually turns to flexibility, serialization, standardization and intelligence. Generally speaking, as long as there are adjustable size detection tools, most parts can be reused, can be called flexible detection tools. The amount of adjustment on the special tester is relatively small, but on the flexible tester, the base and positioning system can be adjusted and reused. Compared with the special checking fixture, it can be applied to various processes, its high flexibility is more suitable for the production of multi-variety mixed line, at the same time, it can reduce the production cost and shorten the preparation period.

The acceptance process of the skylight check fixture needs to consider the evaluation index factors in many aspects. Due to the difference of functions, the structural requirements, technical requirements, precision requirements and material requirements of different check fixtures are also different. Therefore, the acceptance of check fixture should be evaluated one by one according to the specific problems encountered in its use. The evaluation standard of inspection and acceptance, according to the production process of inspection and fixture business, is a unified overall requirement for the whole process of design, manufacture and acceptance of inspection and fixture. Specific measurement standards include the following aspects:

1. Frame and base: Material can be cast aluminum (ZL104), aluminum alloy (LY12) or A3 steel plate. According to the actual production situation of each inspection fixture manufacturers, generally adopt square pipe and steel plate frame welding structure, welding should be solid, there should be no false welding, false welding defects, and carry out aging treatment. The base shall be de-stressed with sufficient strength and stiffness. All steel parts except the base shall be treated with blue. The base of the skylight gauge shall be larger than the assembly, and the excess part shall be used for keeping pins and other measuring instruments.

2. Functional parts: including locating pin, detecting pin and clamping device. Each of the three should comply with the requirements of the technology.

3. Positioning and reference: Positioning shall be stable and reliable, and the positioning mode shall be selected according to the standard requirements; In general, there should be two sets of datum, one set for the hole datum, the other set for the side datum, and can be based on each other.

4. Base level: The lower part of the frame is set as a base level in three directions. The base value is the theoretical coordinate value of the vehicle, which is an integer and marked on the reference plate. The datum must be made by grinding. The base level shall be equipped with superior rubber protective covers.

5. Reference hole: it is based on the reference level. It includes the layout, height, aperture, edge form of the upper surface of the hole, protection measures (such as the configuration of superior rubber jacket), etc. The assembly and individual parts usually adopt two locating pins to locate, and the large and medium-sized parts adopt fixed pins to locate; The small assembly and individual pieces are positioned with fixed pins or latches.

6. Test hole: the aperture should be reasonable, the depth should meet the requirements, and the test pin and the corresponding hole size should also meet the requirements; General hole according to the size of the aperture selection of different lines; The processing method and form of visual inspection hole should be unified. Position accuracy of reference hole, inspection hole, visual hole and counterhole respectively.

7. Bottom foot: the connection mode with the bottom plate, the large gage shall be equipped with roller, and the universal direction shall be equipped with brake.

8. Clamping device: it adopts manual fast clamping device, and the contact parts with stamping parts should be made of elastic non-metallic materials.

9. Card board: Whether the distance between the card board and the skylight gage is consistent, and whether there is a corresponding number for the card gauge and the base.

Up Page:No

Next Page:Design requirements for automotive gauges