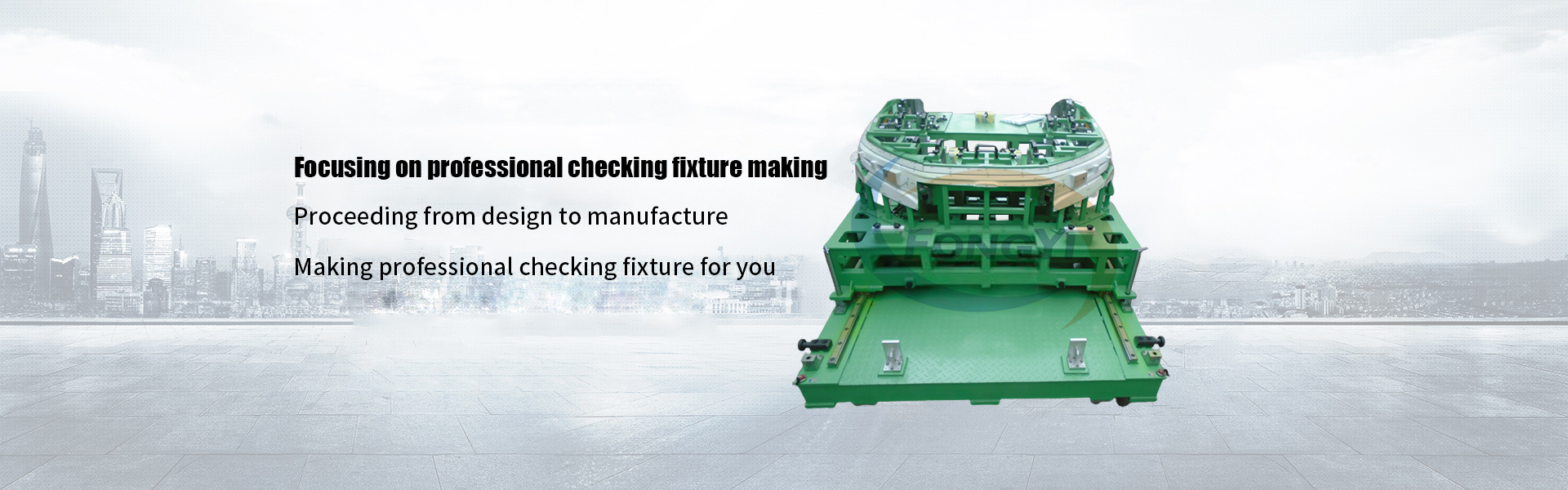

Automobile inspection fixture is a special inspection equipment used to measure and evaluate the dimension and quality of parts. At the scene of the parts production, through the car fixture for the on-line inspection of the parts, so need to install on the fixture parts accurately, and then through the visual, or inventory, or caliper profile for parts, check around, can also with the help of inspection pin or visual components on different properties of hole and the connection position between the parts and parts for visual inspection, to ensure that started in trial production and production implementation parts quality status of rapid judgment. In this case, by visual inspection or measurement, the deviation between the size and shape area around the contour and its relative position and the theoretical value of the gauge processed directly by CAD/CAM can be determined.

Products

contact

DongGuan Fong Yi precision tooling Co.,Ltd.

Address : NO.2,Huamei Road,Xitailong Village Industrial Area, Shatian Town, Dongguan City,Guangdong Province.China

Tel: +86 769 88663970 -2

Fax: +86 769 88663975

E-mail: dgfongyi@vip.163.com;

FongYi Autoparts(WUHAN)CO.,Ltd.

Address : Crossroad between ChangXi and FuJi Road,Changfu Industrial park,Caidian District,WuhanCity,Hubei Province.China

Tel: +86 27 69575831/2/6

Fax: +86 27 69575837

E-mail: whfongyi@vip.163.com;

Industry dynamic

Versatility of automotive gauges

Author:admin Addtion Date:2020-07-01 19:41:07 View:

For some of the most important functional dimensions on the parts, it is also possible to make use of the vehicle inspection tool for numerical detection. The coordinate value of the parts based on the coordinate system of the body can not be obtained directly with the aid of the automobile gage, but by placing the parts on the automobile gage and measuring them with the CMM. The structure of modern automobile check fixture can be used as measuring bracket when designing. However, when the on-line inspection function of the vehicle inspection fixture and the measurement bracket cannot be satisfied at the same time, the on-line inspection function of the vehicle inspection fixture should be satisfied first.

Automobile inspection tools are developed according to the special planning and design requirements of various models. Professional automobile inspection tools can be used to check their dimensions and sizes, and then to carry out measurement and evaluation. They are mainly used for the measurement and adjustment of mold precision in the preparation stage of production and the daily management of size after mass production. For new models, especially for the development of new models, there are few reference materials. At this time, automobile inspection tools can help to quickly carry out debugging, especially when the early parts and equipment are unstable, which can become a reference benchmark. The main body of a vehicle gage is the main frame of the gage, comprising the gage base (i.e. the base level), the vehicle face and the mounting part, which is generally made of epoxy or aluminum.

In the product verification stage, the vehicle inspection fixture can also play a key role, especially in the batch parts * trial assembly stage, a lot of design validation work can be carried out on the main model inspection. In the trial production stage, the conflict between the body in white and the plastic parts inside and outside is often unavoidable. And the vehicle inspection tool can effectively determine the root of the problem, the digital sample car and mass production models and the parts together. So as to guide the modification of non-conforming parts, it points out the direction for product quality improvement. Automotive inspection manufacturing, usually divided into aluminum, resin or iron parts, considering the daily maintenance and service life, we must regularly maintenance and treatment of it, and sometimes have to spray surface treatment.